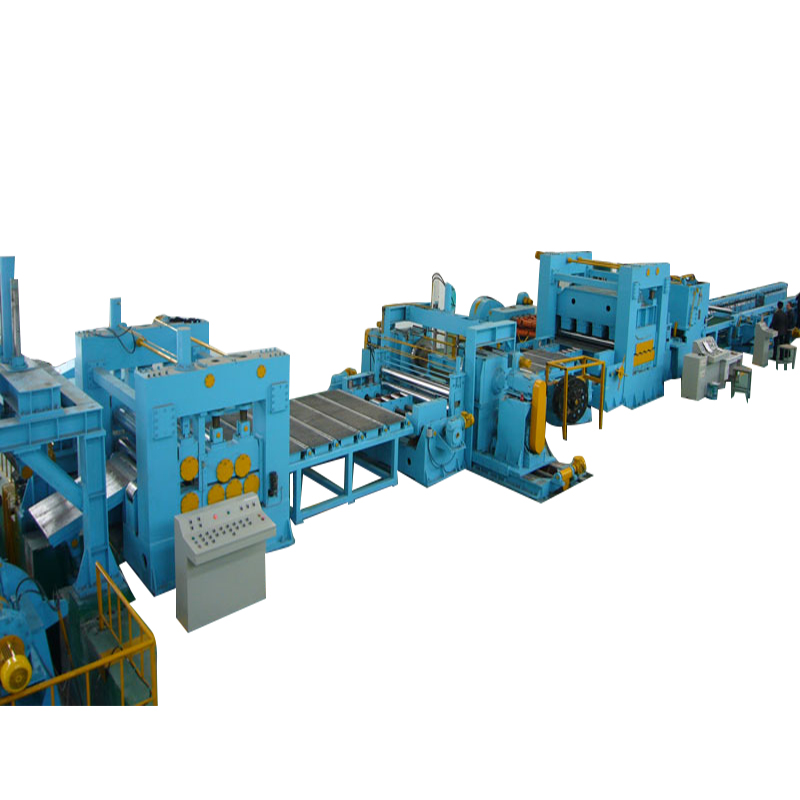

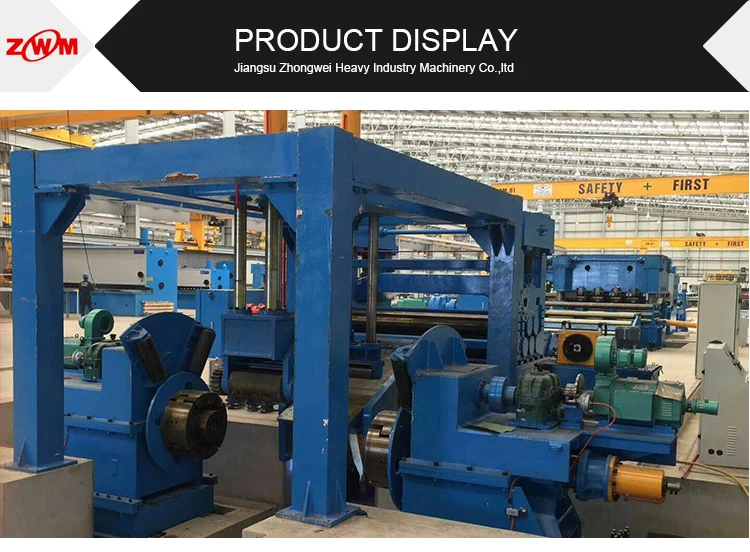

T44QK-Cut To Length Line

Heavy coil cut to length line

high speed galvanized steel coil cutting machine for iron

Feature:

Descriptions for coil cut to length machine cut to length line:

This line is a general leveling unit for metal plates. The multi roll working principle is adopted to make the steel plate repeatedly deform in the positive and negative directions between the leveling work rolls, eliminate the stress and achieve the purpose of leveling.

Main Technical parameters for coil leveling and cutting machine coil cut to length machine cut to length:

|

Name |

Parameter |

Remarks |

|

Thickness |

3~12 mm |

|

|

Width |

500~1000mm |

|

|

Inner diameter of plate |

610-760mm |

|

|

External diameter |

Φ1000mm~Φ2000mm |

|

|

Weight |

Max. 25T |

|

|

Factory room temperature |

≤40°C |

|

|

Leveling speed |

0~30m/min |

|

|

Threading speed |

0~15m/min |

|

|

Fixed length accuracy |

≤±1.0mm/2m |

|

|

Diagonal tolerance |

≤±1.5mm/2m |

|

|

Flatness |

≤±1mm/m2 |

|

|

Floor area of production line |

10000mmx30000mm |

L x W |

|

Total power of production line |

About 350kW |

|

|

Power Supply |

3AC, 380V ± 10%, 50 HZ ± 2% |

|

|

Usage environment |

Local temperature - 10 °C - 40 °C |

|

|

Humidity |

Relative humidity 60% ~ 98% |

|

|

Altitude |

≤1000m |

|

|

Protection level |

Electrical control cabinet and console IP40 |

|

|

Air source pressure |

0.5 ~0.7Mpa |

|

|

Number of operators |

1 main operator and 1-3 auxiliary personnel |

|

|

Equipment painting color |

Host: bright orange (color code: ral2005) Safety protection device: yellow |

|

|

Production line direction |

Face the console from left to right |

|

LIST OF EQUIPMENTS UNDER SCOPE OF SUPPLY for heavy duty aluminum stainless steel ss cut to length automatic cnc metal sheet steel cutting line:

1. Loading car

3. Leading feeding mechanism

4. Roller Leveler+ Concave-convex roller device

5 .Bridge storage silo

6. Corrective devices

7. Main roller leveler

8. Length calculate device

9. Shears

10. Care feeding device

11. Pile material platform

12. Hydraulic System + Pneumatic System

13. Electrical System

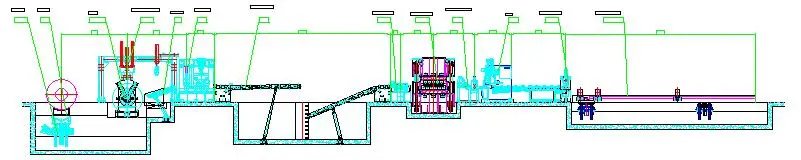

Layout for heavy duty uncoiler, leveling and cutting line of coil steel cutting machine aluminum stainless steel cut to length line:

What is your advantage?

1). Over 40 years experience in manufacturing the machines. Professional and rich experience.

2): We are manufacturer, not the trading company. So we can provide the strong and powerful after sales service.

3): All kinds of processing equipment(17-meter-long large-scale tempering furnace, 20 meters long large CNC five surface machining center, traveling crane of 200 tons capacity, 16m heavy duty lathe) to ensure accuracy.

4): CE, ISO, TUV, BV certificate, Credit AAA enterprise, Famous brand certification, High and new technology enterprise, contract trustworthiness enterprise.

5): ZHONGWEI machines distributeworldwide to about 60 countries and 29 sub-office in China where there are metal plate industry, there are ZHONGWEI machines. And where there are our machines, there are good reputation and terminal user satisfaction.

Do you have after sales support?

We have a 66-person -professional and strong technical support team. And will provide the machine life time service for you. Any problem, contact us and we will solve for you.

How to visit your company?

Our factory is located in Nantong city, near Shanghai. You can fly to Shanghai, then we pick you up from Shanghai airport.

If you visit other cities first, then you can take a high speed train to our city.

What information you need to prepare the quotation:

1. Coil thickness(min-max)

2. Coil width(min-max)

3. What kind of your material(aluminum, mild steel, high strength steel, stainless steel).