Hydraulic Swing Beam Shearing Machine

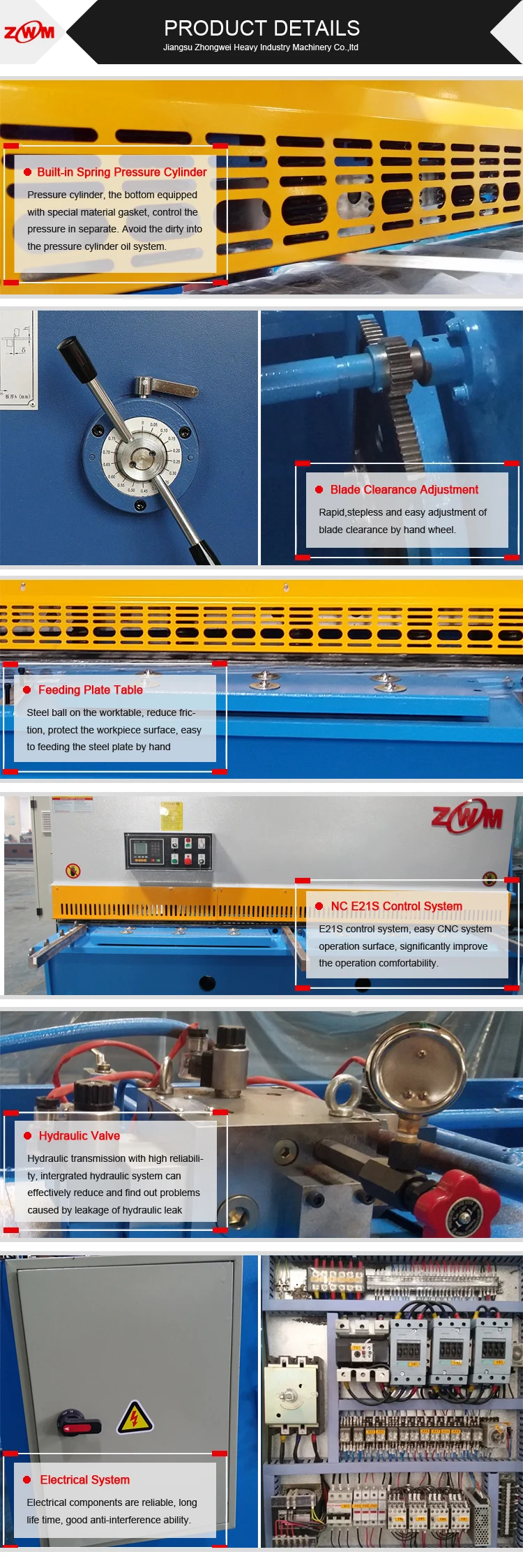

2. The blade’s swing running to carry out shearing by hydraulic driving, running in steady.

3. Light alignment device, convenient for line and manual operation;

4. Reliable integrated hydraulic system; can effectively reduce problems caused by hydraulic oil leakage.

5. NC control system, back gauge moves fast, numerical display, closed-loop control system, ensures a higher cutting accuracy, CNC system has precision compensation and automatic detection and other additional function;

6. Humanistic concern security design in all details

STANDARD EQUIPMENTS

• Mainly Siemens Electric System, high stability.

• Rexroth or Alpha hydraulic system.

• Siemens motor

• Hold down cylinders.

• Moveable foot switch.

• Hand wheel to rapidly and accurately adjust the blade clearance.

• Good quality Japanese Valqua seal to prevent leakage of oil

• FILTER in the oil tank.

• Sheet feeding table.

• Hardened blades.

- Top blades : 2 sides

- Bottom blades : 4 sides

• E21S NC controller.

Program memory of up to 40 programs, up to 25 steps per program

Back gauge retract function

One key backup/restore

mm/inch

Chinese/English

• Protective fence which are meet with CE standards, to ensure the operation safety.

• Foldable finger protection guard.

• Emergency stop button.

• 100mm throat depth.

• 20-600mm motorized back gauge with 0.1 mm accuracy.

• 800mm side gauge and front support arms.

• Metric and inch rulers.

OPTIONAL EQUIPMENTS

• bigger throat depth.

• Front angle gauge.

• Side gauge and front support arms in optional lengths.

• Optional back gauge stroke.

• Ball screw with linear guide

• Delem DAC 310 or Estun E200P CNC system

• Motor driven blade gap distance control

• Sheet conveyor and stacking system.

• Sheet support system for thin sheets.

1- Pneumatic support system. (Lever type)

2- Pneumatic support system. (Monobloc panel type)

• REAR DOOR WITH PHOTO-ELECTRIC PROTECTION

• Hydraulic oil cooling and heating system.

• Coolant system or heater can be placed in electric panel during ambient conditions.

• Optional front feeding table.

• Blades special for cutting stainless steel.

• Ability to increase stroke amount per minute.

• Customized colors.

• Double foot pedal.

• Electrical panel or controller can be placed on right side of the machine.

• Central lubrication system.

| MODEL | THICKNESS | WIDTH | ANGLE | STROKE | BACKGAUGE | MOTOR | DIMENSION |

| mm | mm | ° | min -1 | mm | kw | mm | |

| 4x2500 | 4 | 2500 | 1.5 | 10—18 | 20-460 | 4 | 3100x1300x1600 |

| 4x3200 | 4 | 3200 | 1.5 | 8—18 | 20-580 | 5.5 | 3900x1660x1680 |

| 4x4000 | 4 | 4000 | 1.5 | 8—12 | 20-580 | 5.5 | 4680x2000x1700 |

| 6x2500 | 6 | 2500 | 1.5 | 10—18 | 20-580 | 7.5 | 3130x1495x1620 |

| 6x3200 | 6 | 3200 | 1.5 | 8—14 | 20-580 | 7.5 | 3770x1745x1680 |

| 6x4000 | 6 | 4000 | 1.5 | 8—12 | 20-580 | 7.5 | 4606x1875x1650 |

| 6x6000 | 6 | 6000 | 1.5 | 5—7 | 20-800 | 11 | 6700x2130x2170 |

| 8x2500 | 8 | 2500 | 1.5 | 10—14 | 20-580 | 11 | 3130x1610x1640 |

| 8x3200 | 8 | 3200 | 1.5 | 8—10 | 20-580 | 11 | 3630x1780x1700 |

| 8x4000 | 8 | 4000 | 1.5 | 8—8 | 20-580 | 11 | 4610x1900x1720 |

| 8x6000 | 8 | 6000 | 1.5 | 5—6 | 20-800 | 15 | 6700x2220x2220 |

| 8x8000 | 8 | 8000 | 1.5 | 3—5 | 20-800 | 15 | 9000x2500x2600 |

| 10x2500 | 10 | 2500 | 1.5 | 6—10 | 20-580 | 15 | 3200x1900x1820 |

| 10x3200 | 10 | 3200 | 1.5 | 5—10 | 20-580 | 15 | 3915x2040x1920 |

| 10x4000 | 10 | 4000 | 1.5 | 4—8 | 20-580 | 15 | 4610x1900x1720 |

| 12x2500 | 12 | 2500 | 1.5 | 5—10 | 20-580 | 18.5 | 3215x1910x1830 |

| 12x3200 | 12 | 3200 | 1.5 | 4—9 | 20-600 | 18.5 | 3915x2040x1920 |

| 12x4000 | 12 | 4000 | 1.5 | 4—8 | 20-800 | 18.5 | 4715x2250x1970 |

| 12x6000 | 12 | 6000 | 1.5 | 3—6 | 20-800 | 30 | 6800x2750x2580 |

| 12x8000 | 12 | 8000 | 2 | 3—5 | 20-800 | 37 | 9000x3100x3300 |

| 16x2500 | 16 | 2500 | 2 | 8 | 20-600 | 22 | 3200x2100x1930 |

| 16x3200 | 16 | 3200 | 2 | 7 | 20-600 | 22 | 3900x2250x2050 |

| 16x4000 | 16 | 4000 | 2 | 5 | 20-800 | 22 | 4700x2600x2120 |

| 20x2500 | 20 | 2500 | 2.5 | 6 | 20-800 | 30 | 3150x2300x2080 |

| 20x3200 | 20 | 3200 | 2.5 | 6 | 20-800 | 30 | 3945x2670x2350 |