WE67K Large Size CNC Press Brake

| Specifications | Nominal force | Lenghth of worktable | Distance between column | Slider stroke | Open Height | Throat depth | Drive speed | Working speed | Return speed | Main motor power | Weight |

| KN | mm | mm | mm | mm | mm | mm/s | mm/s | mm/s | KW | Kgs | |

| WE67K-63/2500 | 630 | 2500 | 2100 | 175 | 400 | 350 | 130 | 10 | 130 | 5.5 | 4000 |

| WE67K-80/2500 | 800 | 2500 | 2100 | 200 | 440 | 350 | 90 | 12 | 90 | 7.5 | 5000 |

| WE67K-100/2500 | 1000 | 2500 | 2000 | 200 | 440 | 410 | 120 | 12 | 120 | 11 | 5500 |

| WE67K-100/3200 | 1000 | 3200 | 2700 | 200 | 440 | 410 | 130 | 10 | 130 | 11 | 6500 |

| WE67K-100/4000 | 1000 | 4000 | 3500 | 200 | 440 | 410 | 130 | 10 | 130 | 11 | 7000 |

| WE67K-125/2500 | 1250 | 2500 | 2000 | 200 | 440 | 410 | 130 | 10 | 130 | 11 | 6000 |

| WE67K-125/3200 | 1250 | 3200 | 2700 | 200 | 440 | 410 | 130 | 10 | 130 | 11 | 6900 |

| WE67K-125/4000 | 1250 | 4000 | 3500 | 200 | 440 | 410 | 130 | 10 | 130 | 11 | 7200 |

| WE67K-160/2500 | 1600 | 2500 | 2000 | 200 | 440 | 410 | 130 | 9 | 100 | 15 | 7800 |

| WE67K-160/3200 | 1600 | 3200 | 2700 | 200 | 440 | 410 | 100 | 10 | 100 | 15 | 9000 |

| WE67K-160/4000 | 1600 | 4000 | 3500 | 200 | 440 | 410 | 130 | 10 | 130 | 15 | 10800 |

| WE67K-200/2500 | 2000 | 2500 | 2000 | 250 | 440 | 410 | 100 | 10 | 100 | 18.5 | 9000 |

| WE67K-200/3200 | 2000 | 3200 | 2700 | 250 | 440 | 410 | 100 | 8 | 100 | 18.5 | 10500 |

| WE67K-200/4000 | 2000 | 4000 | 3500 | 250 | 450 | 410 | 130 | 10 | 105 | 18.5 | 12000 |

| WE67K-250/2500 | 2500 | 2500 | 2000 | 250 | 450 | 410 | 100 | 8 | 100 | 18.5 | 10500 |

| WE67K-250/3200 | 2500 | 3200 | 2700 | 250 | 450 | 410 | 100 | 8 | 100 | 18.5 | 14000 |

| WE67K-250/4000 | 2500 | 4000 | 3500 | 250 | 520 | 410 | 100 | 8 | 100 | 18.5 | 16000 |

| WE67K-300/2500 | 3000 | 2500 | 2000 | 250 | 500 | 410 | 100 | 8 | 100 | 22 | 14000 |

| WE67K-300/3200 | 3000 | 3200 | 2700 | 250 | 500 | 410 | 120 | 8 | 100 | 22 | 18000 |

| WE67K-300/4000 | 3000 | 4000 | 3500 | 250 | 500 | 410 | 100 | 8 | 100 | 22 | 18500 |

| WE67K-300/6000 | 3000 | 6000 | 4700 | 250 | 550 | 400 | 70 | 9 | 70 | 22 | 27000 |

| WE67K-400/3200 | 4000 | 3200 | 2500 | 300 | 600 | 400 | 80 | 7 | 60 | 30 | 22000 |

| WE67K-400/4000 | 4000 | 4000 | 3200 | 300 | 600 | 400 | 70 | 7 | 70 | 30 | 24000 |

| WE67K-500/4000 | 5000 | 4000 | 3100 | 320 | 625 | 500 | 70 | 7 | 70 | 37 | 32000 |

| WE67K-500/5000 | 5000 | 5000 | 4000 | 320 | 625 | 500 | 70 | 7 | 70 | 37 | 35000 |

| WE67K-600/4000 | 6000 | 4000 | 3200 | 300 | 650 | 500 | 80 | 8 | 80 | 45 | 42000 |

| WE67K-600/6000 | 6000 | 6000 | 4800 | 300 | 650 | 500 | 70 | 7 | 70 | 45 | 60000 |

| WE67K-800/6000 | 8000 | 6000 | 4500 | 400 | 700 | 600 | 70 | 8 | 70 | 55 | 70000 |

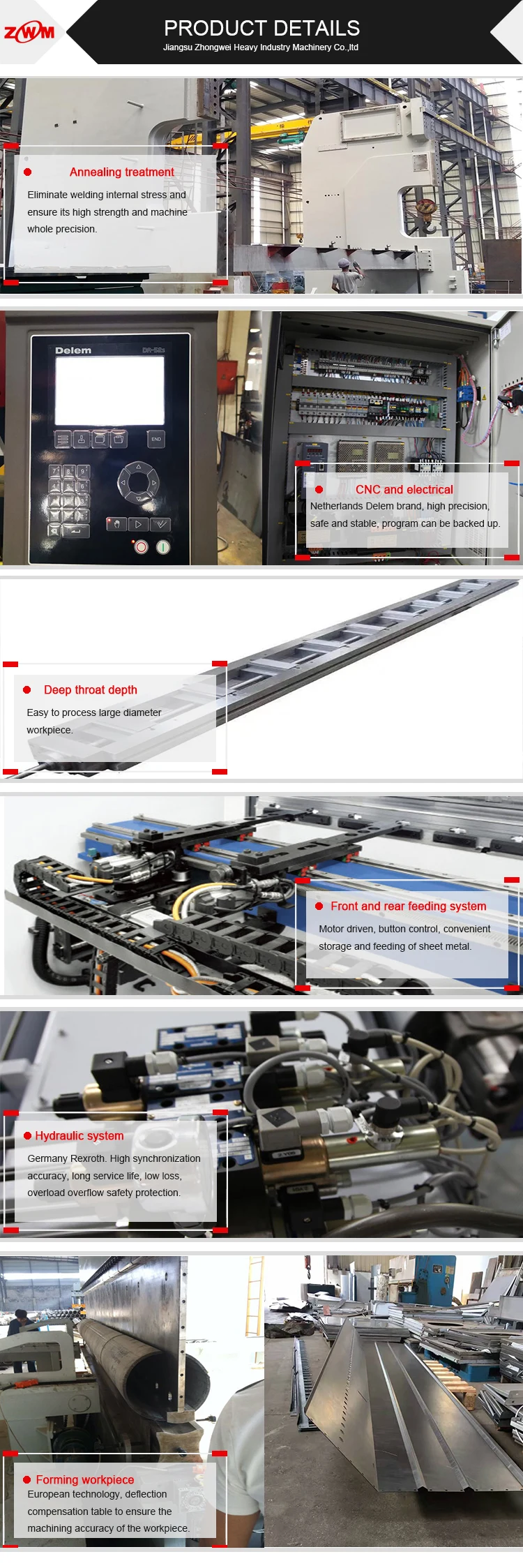

Performance:

1. Electro-hydraulic servo system,closed loop controls slider operation accuracy.

2. The unique patented technology: large press double side deflection compensation .

3. The new Delem DA66T 3D & 2D graphical touch screen Multi axis controller which is a very user friendly and intuitive programming unit are fitted with the 4 axis MB8 CNC Press Brakes.

4. Open adjustable insert die, suitable for various workpieces.

5. Various auxiliary organizations can meet the needs of users and make the process more convenient and efficient.

6. The frame of machine is composed of tank, working table, left and right housings and slider. So it has high strength and good rigidity. Also it needs vibration to remove stress.

7.Through the computer, the operator can communicate with the machine.

8. Equipped with good guidance system, position measurement system and hydraulic balance system, it can meet the requirements of full length operation and eccentric operation.

9. The workbench compensation device is used to compensate the deflection of the machine tool when working to ensure the accuracy of the workpiece.

10. The surface of the cylinder has good wear resistance and heat treatment, long service life and good lubrication performance.

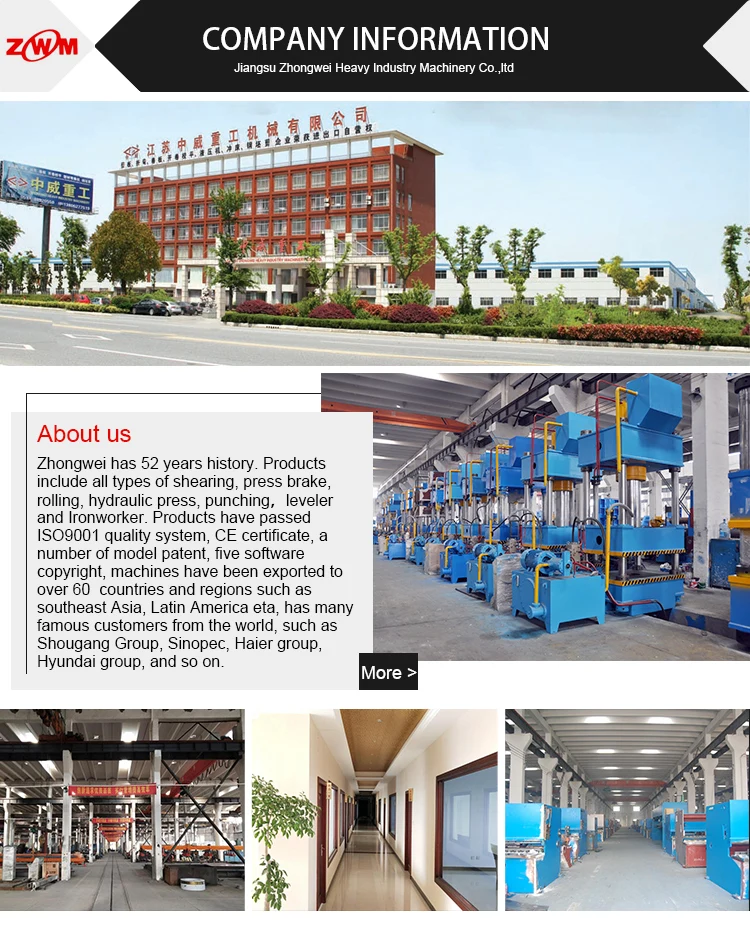

What is your advantage?

1). Over 40 years experience in manufacturing the machines. Professional and rich experience.

2): We are manufacturer, not the trading company. So we can provide the strong and powerful after

sales service.

3): All kinds of processing equipment(17-meter-long large-scale tempering furnace, 20 meters long

large CNC five surface machining center, traveling crane of 200 tons capacity, 16m heavy duty lathe)

to ensure accuracy.

4): CE, ISO, TUV, BV certificate, Credit AAA enterprise, Famous brand certification, High and new

technology enterprise, contract trustworthiness enterprise.

5): ZHONGWEI machines distributeworldwide to about 60 countries and 29 sub-office in China where

there are metal plate industry, there are ZHONGWEI machines. And where there are our machines,

there are good reputation and terminal user satisfaction.

Do you have after sales support?

We have a 66-person -professional and strong technical support team. And will provide the machine life

time service for you. Any problem, contact us and we will solve for you.

How to visit your company?

Our factory is located in Nantong city, near Shanghai. You can fly to Shanghai, then we pick you up from

Shanghai airport.

If you visit other cities first, then you can take a high speed train to our city.

What information you need to prepare the quotation:

1. Sheet thickness(min-max)

2. Sheet width(min-max)

3. What kind of your material(aluminum, mild steel, high strength steel, stainless steel).

4. Bending shape or Product drawing after bending